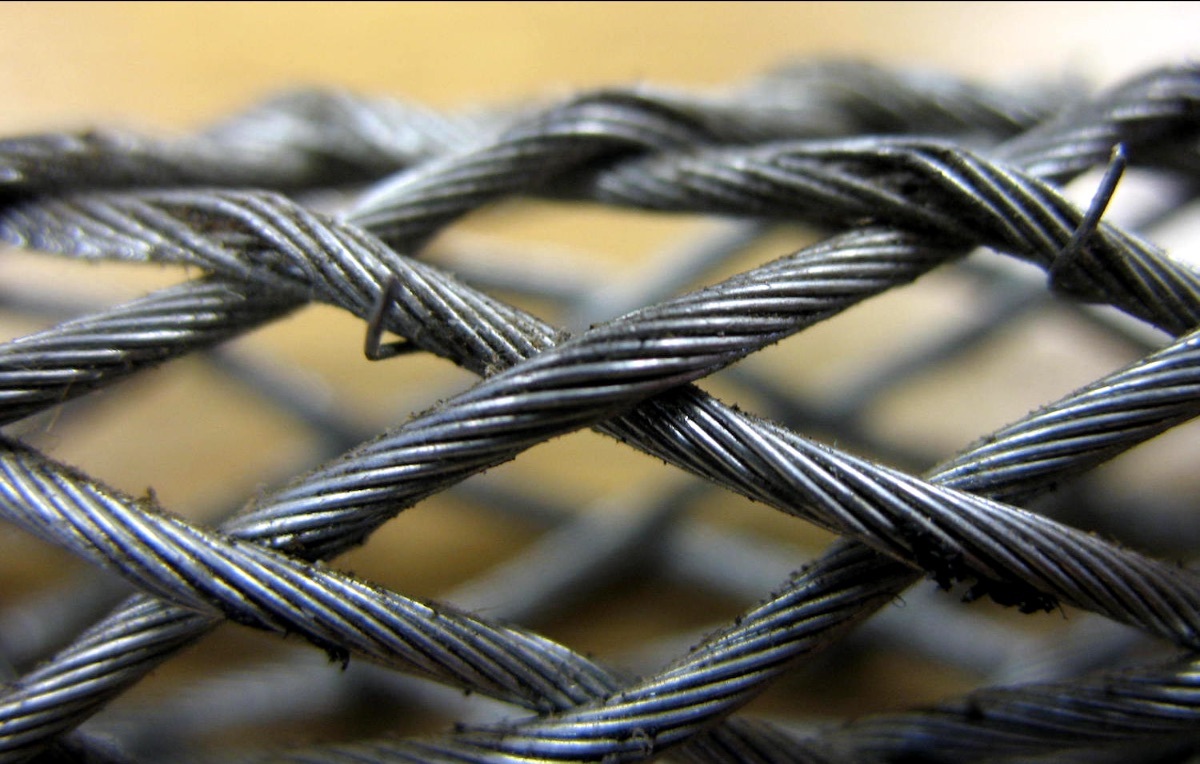

Inspecting a cable sock is crucially important to ensure safe pulling operations, maximum sock strength and performance.

There are a number of variables that can weaken a cable sock which is why visual inspection of used socks is so important. There are some simple checks that you can do routinely to mitigate potential accidents from happening when you reuse a sock.

When inspecting a cable sock, identifying potential damage and trouble spots is key. Our Engineering team has compiled a summary of the types of damage you need to be aware of prior to beginning any pulling project with used cable socks, making the decision of whether to re-use a sock easier.

Download your exclusive copy of the report, or If you need further technical advice, please get in touch.

Written and Published by Slingco.

Inspecting a cable sock is crucially important to ensure safe pulling operations, maximum sock strength and performance.

LEARN MORE

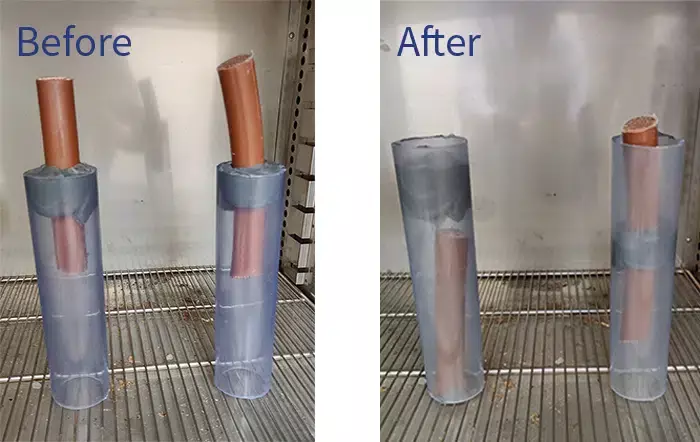

The fast and effective repair of power transformer oil or SF6 leaks is an important part of a consistent power supply that minimize economic losses for both power utilities and their customers.

LEARN MORE

The most frequently asked questions regarding cable pulling and lubrication.

LEARN MORE

This guide to Understanding Exposure to Electrical Cleaning Solvent Vapors.

READ MORE

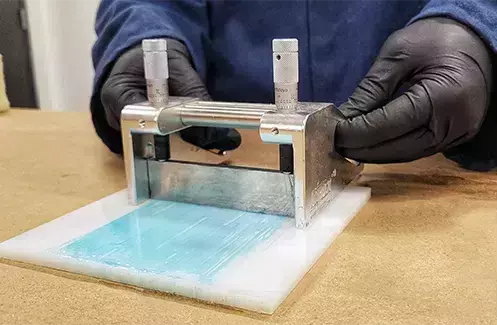

How much cable pulling lubricant is needed to safely install cable? The answer is simple...

READ MORE

Duct Putty is commonly used to seal electrical and communications duct worldwide, but falls seriously short of expectations.

READ MORE

Contact us

"Powerhowse Electric offers quality electrical supplies. Contact us today for more information or to place an order!"

Contact us